G-823A, G-864, and MagArrow Magnetometers

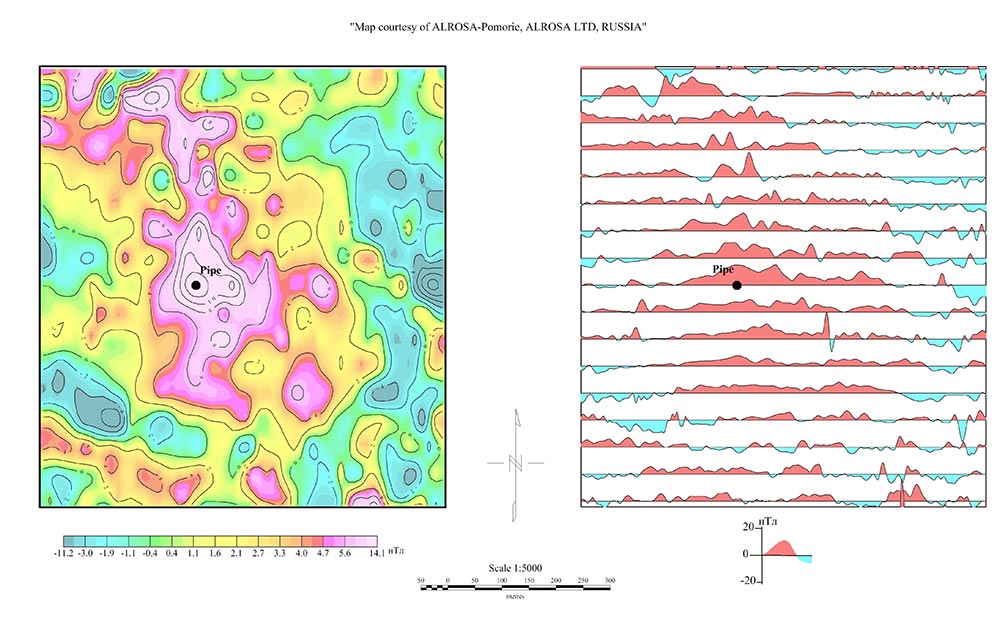

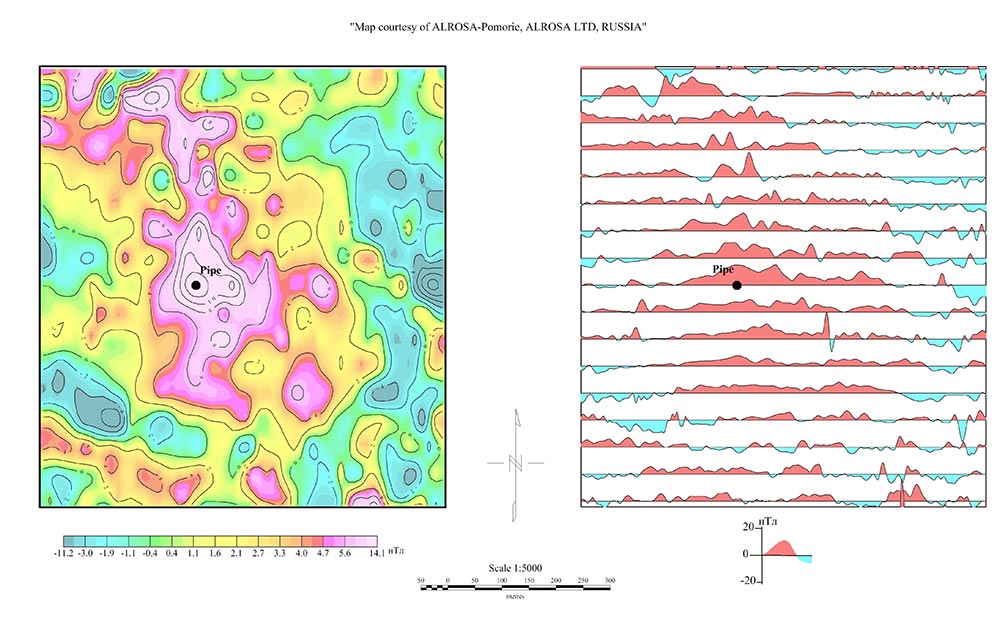

Although magnetic surveys are used to measure ferrous objects or minerals, they may also be used to locate minerals that are not magnetic, such as diamonds or gold. Pyrrhotite and magnetite are the primary magnetic minerals, and they are naturally found in both host rocks and some forms of alteration associated with mineral deposits. Kimberlite, the host rock to most of the world’s naturally occurring diamonds, is composed primarily of carbonate, mica, olivine, and pyroxene. Of these, olivine is the primary magnetic mineral gives the kimberlite its magnetic signature. Researchers believe that diamonds do not form in the kimberlite, but are instead carried upward in the high-pressure eruptions. Kimberlite pipes are thought to originate in the mantle and are the result of explosive eruptions traveling upward through the crust at approximately 400 meters per second. At a depth of a few kilometers beneath the land surface, the lateral earth pressures decrease enough to allow the kimberlite magma, rich in CO2 gas, to start expanding, with the resulting ore body being roughly carrot shaped.

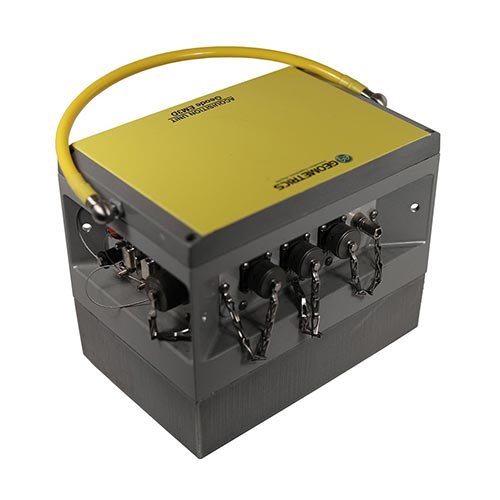

Magnetic surveys are the primary geophysical technique used in kimberlite exploration. The magnetic signature is typically recognized as 3 to 10 circular or elliptical pipes clustered closely together. Typically, exploration begins by collecting magnetic data using a magnetometer mounted on a fixed-wing helicopter or airplane. The G-823A Magnetometer, has the highest possible standards for airborne, land or marine surveys, meeting rigorous vibration and environmental testing standards. The system’s high performance and multi-function capability are excellent for mapping geologic structure or for mineral exploration.

For higher-resolution magnetic surveys across areas too small to fly but too large to cover on foot, the MagArrow UAS-Enabled Magnetometer fills the gap. The MagArrow can be flown over areas typically inaccessible to high-resolution magnetic surveys, and all while collecting data up to 10x faster than a traditional walking survey.

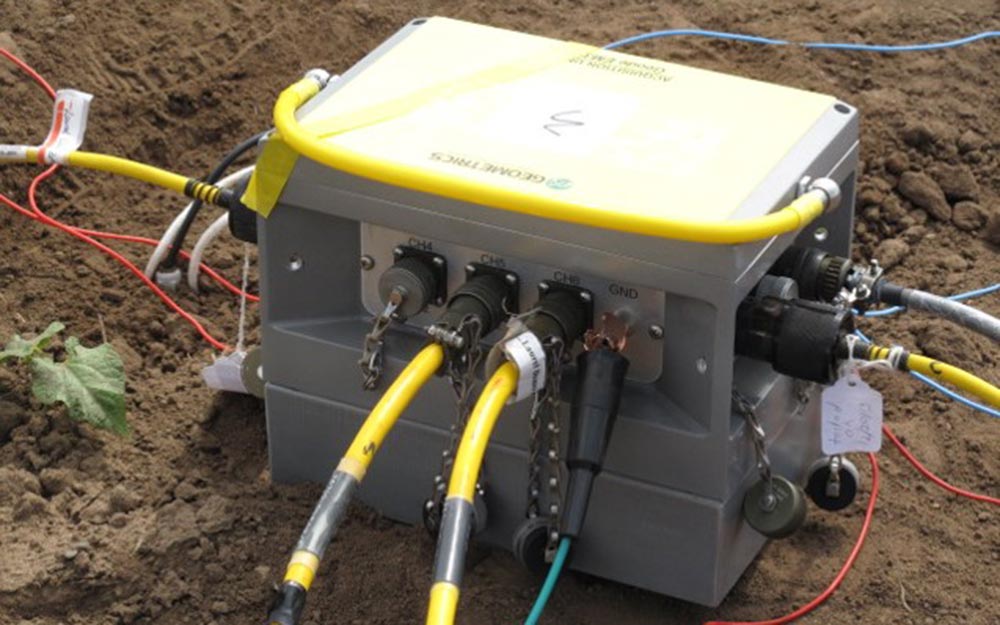

After targets are identified, land-based magnetic surveys allow for closer line spacing and higher data resolution. The G-864 Magnetometer is our latest land magnetometer, incorporating Geometrics’ quality with the latest in modern technology. The G-864 works with our Android Acquisition software and allows the user to collect data using any Android device. Save time in the field by defining your geometry in advance, and then visualize your data on a color map before leaving the site. A modern user interface allows you to cover more area faster, lowering your survey costs while still providing top quality data.