Description

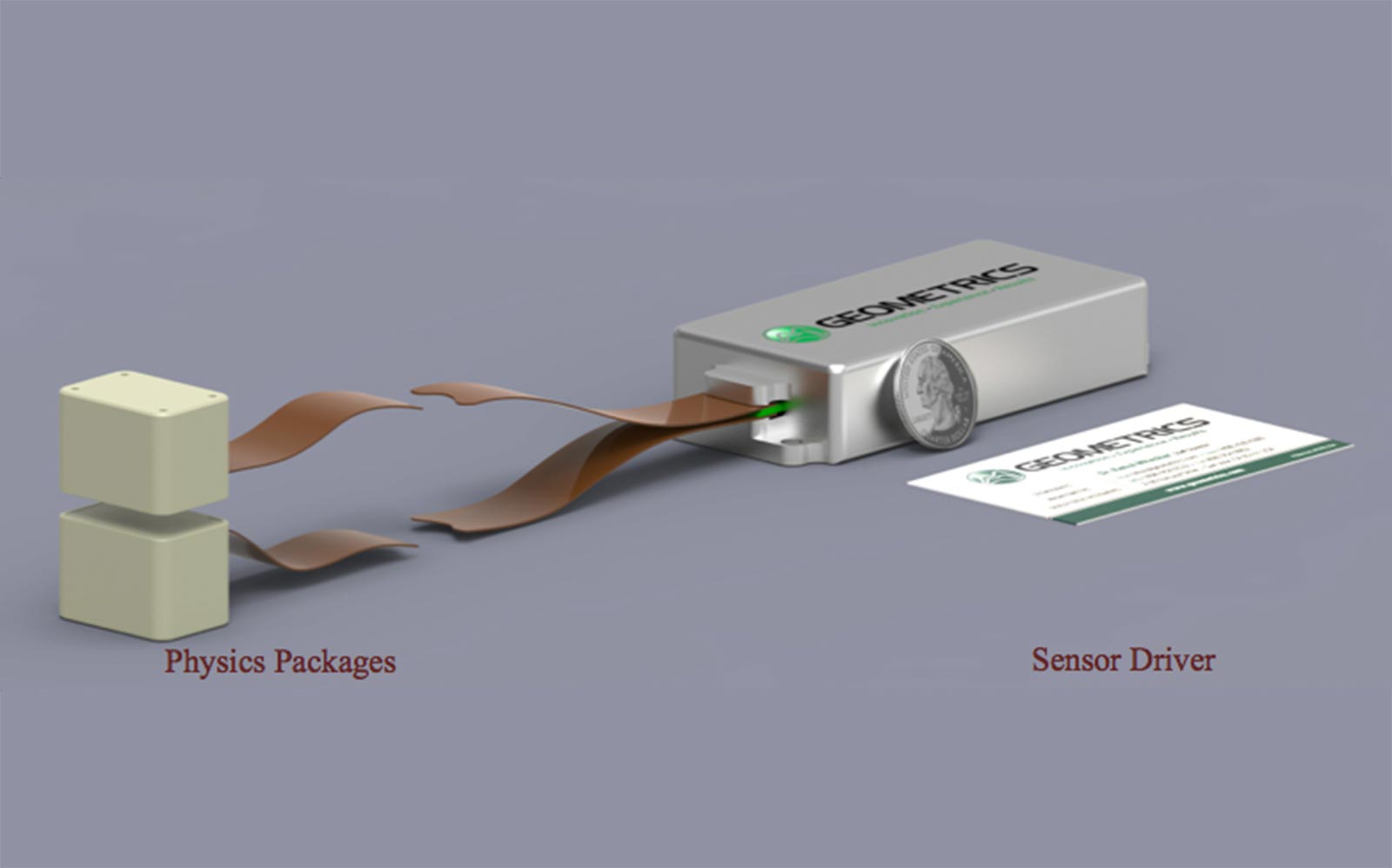

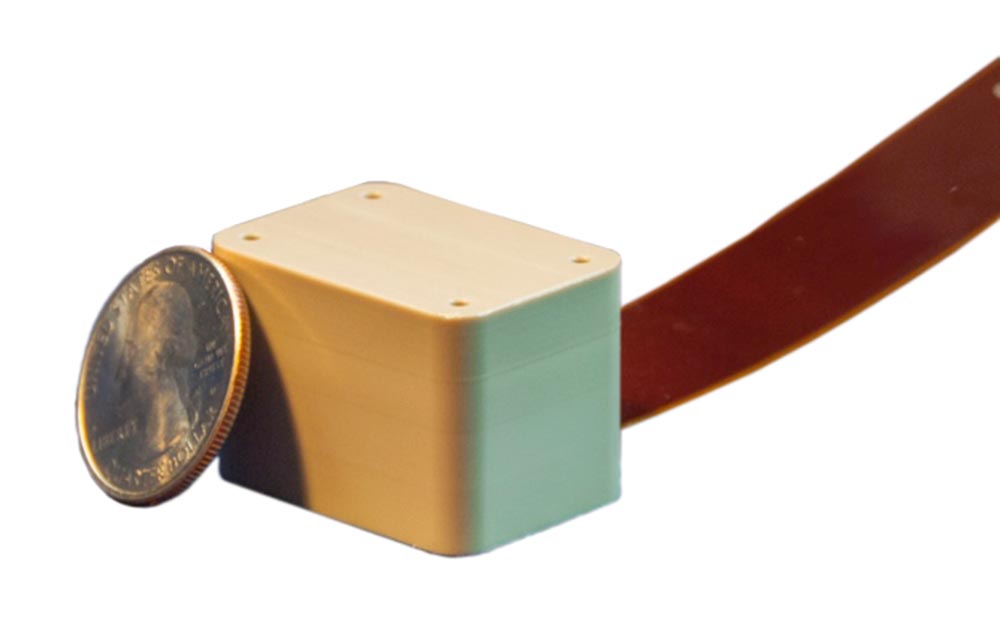

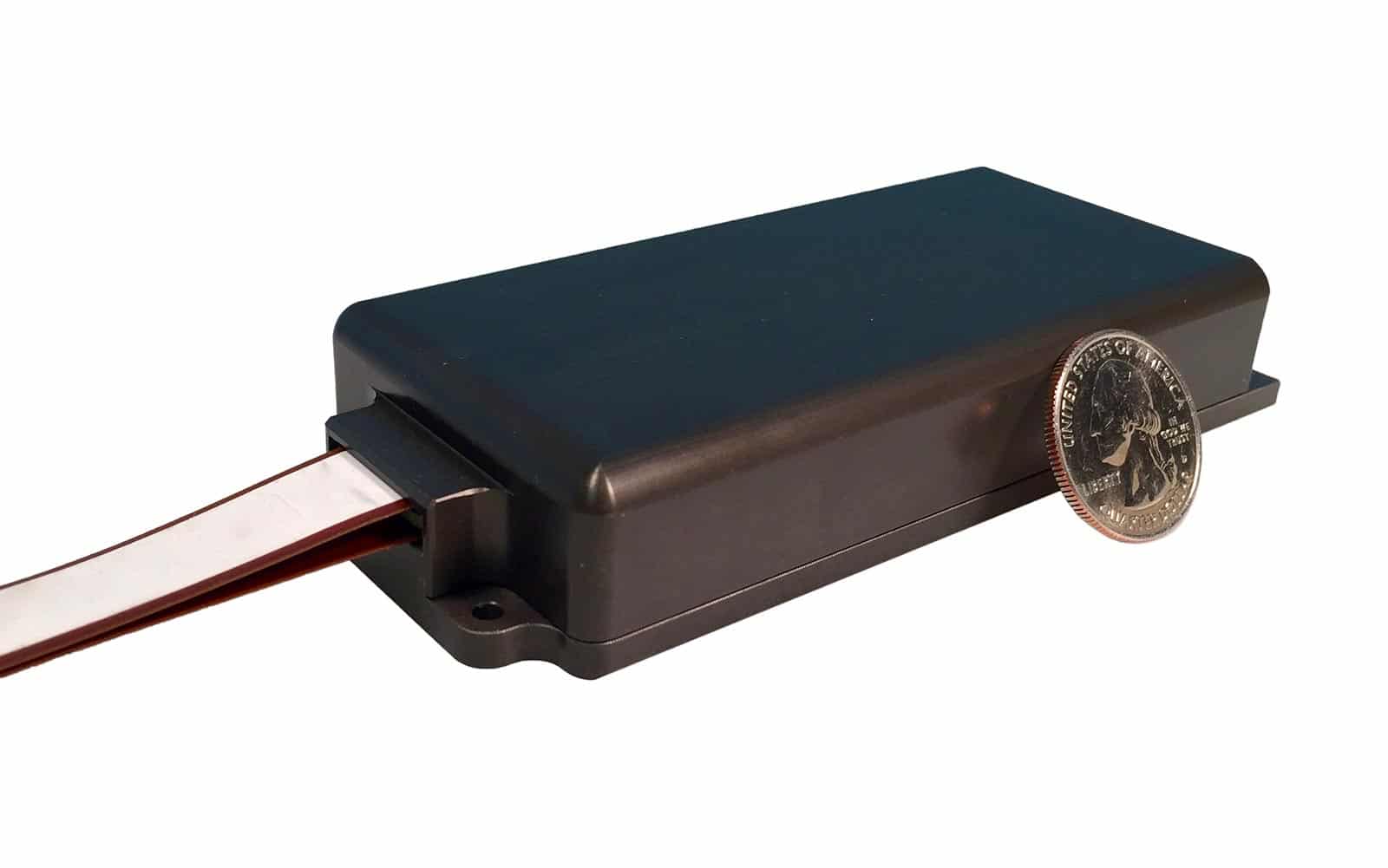

Geometrics has recently announced a revolutionary new line of magnetometer products based on recent research in miniaturizing atomic clocks and magnetometers. Advances by Geometrics allow for a 10-fold reduction in size and power consumption without sacrificing performance. New devices soon to be on the market are only about 15cc in size, and require only 2W per sensor. Manufacturing technologies for an additional 10-fold reduction in size and power consumption are available now. Recent advances in laser technology and MEMS fabrication techniques, supported by the Defense Advanced Research Projects Agency (DARPA) and the Strategic Environmental Research and Development Program (SERDP) , have led to miniaturized components for atomic clocks and magnetometers. Using its long experience in building field-rugged magnetometers, Geometrics has recently achieved the breakthroughs necessary in sensor and electronics design to bring cost-effective, reliable products to market. This advancement in sensing technology will make an enormous impact on sensing and detection applications. Many applications could benefit from lower cost, lower power sensors. Some applications will use a relatively small number of sensors, and others will create demand for a huge number of sensors. These applications and the required production technology must be carefully choreographed for the successful launching of this technology. We recognize that each customer has unique needs, so in order to better meet those needs we have created four different sensors, each with different technical specifications. These sensors are the Low-Noise MFAM, Low-Heading Error MFAM, Super-MFAM (combining the low-noise and low heading error configurations into the same MFAM Module) and the SX-MFAM for export compliance. To see the specifications of each, please refer to the "Spec Sheet" available for download below.Features and benefits

MFAM Module- Dual-Sensor Module: Two sensors allow for individual or gradient measurements. Reconfigure sensors to achieve dead-zone free operation anywhere in the world. Also allows for heading error compensation

- Small Size: No significant weight increase when added to existing instruments or systems.

- Low Power Operation: Decrease downtime by operating longer on a smaller battery.

- Modular Architecture: Integrate the MFAM module into your existing instruments and expand your service line.

- High Performance: Fast sampling and low noise allow for use in a variety of applications, including geophysics, non-destructive evaluation, magnetocardiography, and structural health fields.

- Four Analog Input Channels: Differential and scalable inputs for versatile integration.

- Power over Ethernet (PoE) Support: Single connection for power and downloading data.

- On-board GPS: GPS provides position and 1PPS controls measurement timing.

- Temperature/Pressure/Humidity Sensor: Understand environmental conditions.

- 10 MHz Reference Input: Allows the disciplining of master system clock.

- Schematics and Example Source Code Provided: Modify code as needed for interface requirements and use schematics to start a custom board layout.

- Click here for the Development Kit User Manual.

Technical Details

MFAM Specification List

MFAM Pin Configuration

Differences between LCS050G (Low-Noise) vs. LCS100S (SuperMag) modules

Cannot Connect to the MFAM Dev Kit through the Ethernet

How to switch the operating mode for SuperMag (LCS100S) MFAM?

How to set up dead-zone-free operation for MFAM

MFAM Developer Kit Shipping Weights & DIMS

Downloads

TYPICAL USES

- Novel UAS Applications: Wellhead locating, pipeline tracking, utility surveying, and more

- Security and Detection Applications: A small unit size, low power requirements, and high sensitivity allow for perimeter monitoring applications.

- Marine Magnetometry Investigations: Customizable architecture allows for integration with autonomous or manned underwater vehicles.

- For additional information on MFAM Applications, click here