General information

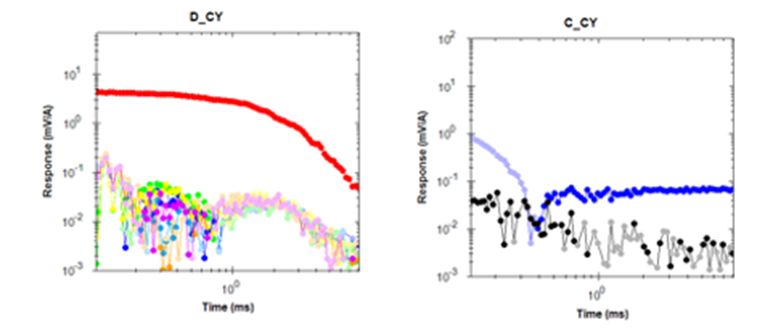

The most common symptoms of intermittent connection issues are shown below: D_CY shows a background decay signal is either much higher than normal, and/or C_CY is a flat line (doesn’t decay).

Figure 1 Intermittent connection issue.

Where is the failure occurring?

The two most common places where intermittent issues occur are at the two ends of the Rx cable: the joint between the Rx cable and the Cart and the joint between the Rx cable and the EDA box (orange box).

Now we need to identify which joint has the intermittent issue.

- Set up the MM2x2 in DAM mode.

- Collect DAM data while keeping the Cart stationary but tapping one joint.

- Collect another DAM data while tapping the other joint.

- Analyze the DAM data by plotting the “Monostatic_5” for all 12 Rx channels in Geosoft. The channels having intermittent issues will appear much noisier.

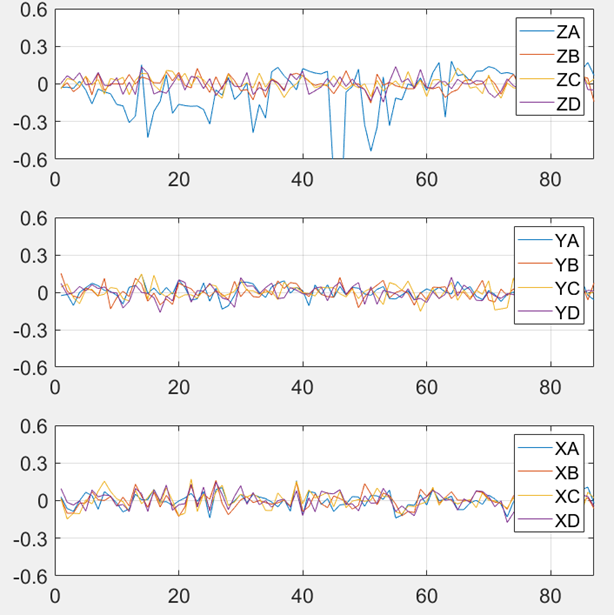

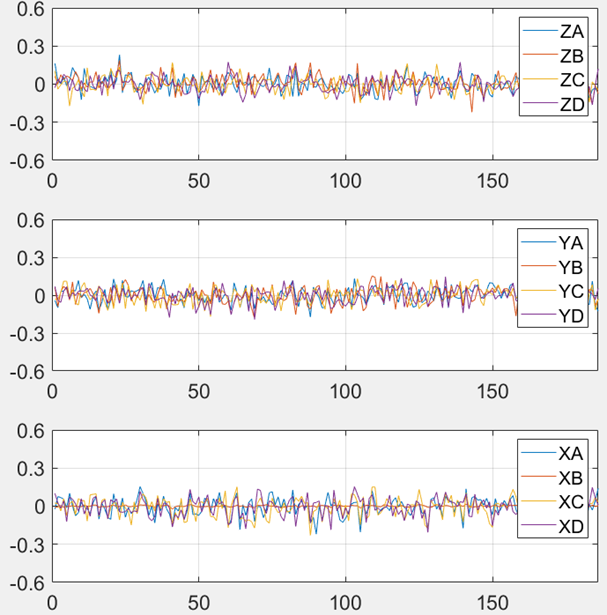

- If you have MatLab software, you can download the MatLab code to analyze the DAM data. Example plots are shown below. It is obvious that “ZA” channel has the intermittent issue in Figure 2 and “XB” channel is open in Figure 3 (very flat line, no noise at all). Click here to download the code:

.

- If both DAM and IVS data have the same problematic channel(s), we are confident that the intermittent issues observed in IVS data are repeated in DAM data, and by tapping at that location, we are able to identify the intermittent joint.

Figure 2 Intermittent "ZA" channel.

Figure 3 Open "XB" channel.

What to do next?

- Disconnect the problematic joint and clean the connectors on both sides thoroughly (using an acid brush and a can of compressed air). Reconnect and try the tapping method again. If the problem goes away (no more noisy channels), the intermittent issue is likely caused by dust.

- If cleaning doesn’t fix the problem, swap out the Rx cable and repeat the tapping method. If the problem goes away, it is likely caused by a bad Rx cable.

- If there is another set of EDA and Cart available, swap out the EDA and the Cart to identify the problematic part.

- If not, use the tapping location to identify the problematic part.

- Fill out the RMA form at https://www.geometrics.com/return-material-authorization/ .

- If it is the Cart, send in the whole system for inspection/repair. You can contact Geometrics for MM2x2 rental if you need to continue your work during the down time.

- If it is the EDA, we recommend sending in the EDA only. It will save your repair time since it is much faster to unpack/pack/ship the EDA than the whole system. You can contact Geometrics for EDA rental if you need to continue your work during the down time.

Warning

Please note that this tapping method should ONLY be tried when intermittent issues have been observed in IVS tests. It is NOT recommended to use it as a daily QC test because it does put extra stress on connectors and likely leads to a shortened connector lifetime if applied too often.